Composite components currently have a disadvantage in terms of cycle time when pressing. This results in high costs for pressing large quantities, especially for applications in the automotive industry. Due to the high demand for lightweight components, there has also been a greater demand for very fast curing prepreg systems in the last few years.

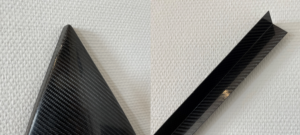

CeTePox® AM XP 222 A/ AM 5597/ 2021-2 C3/ AM XP 317 C is a high transparency 4K prepreg system for pre-impregnation of composite fibres such as carbon, glass and aramid. This low tack system is developed especially for compression moulding processes and enables demoulding under hot conditions (Hot-In/Hot-Out). The system allows very short cycle time and can be cured at 135 °C tool temperature in less than 3 minutes. Curing at 150 °C enables the system to be demolded within 2 minutes depending on tool and process conditions. Overall, the advantages of this system allow easy scaling of process size to high volume production of geometrically simple structural elements to visible components.

Deutsch

Deutsch